|

Gradient Diamond strictly follows ISO 9001-2015 quality management system. Our QC guarantees the tightest possible particle size distribution within every batch, we use a wide range of processes designed to ensure that customers receive a consistent finish and removal rates in every batch.Gradient diamond powder products passed strict multi-point quality inspection process to ensure our products meet or exceed customer expectations. Our multi-point quality inspection procedure includes size analysis, shape analysis, toughness index, size distribution, impurity. |

Toughness Index(Ti)Toughness Index (TI): test to determine the relative strength of the diamond particles. The aim of this test is to determine the particle size after the material is subjected to controlled crushing. |

|

|

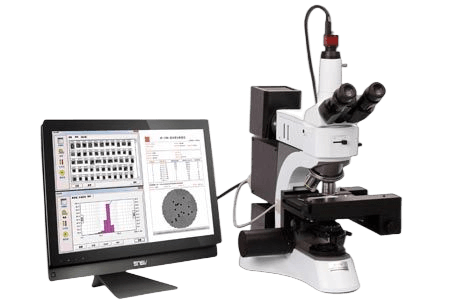

Optical Microscope Based Image Analysis"Seeing is believing", Gradient Diamond offers customers photos of its orders.In addition to the quantitative analysis provided by the wide range of Gradient Diamond measuring equipment, these Microscope images allow you to "examine" your shipment of our Micron Diamond powders, and compare different batches. |

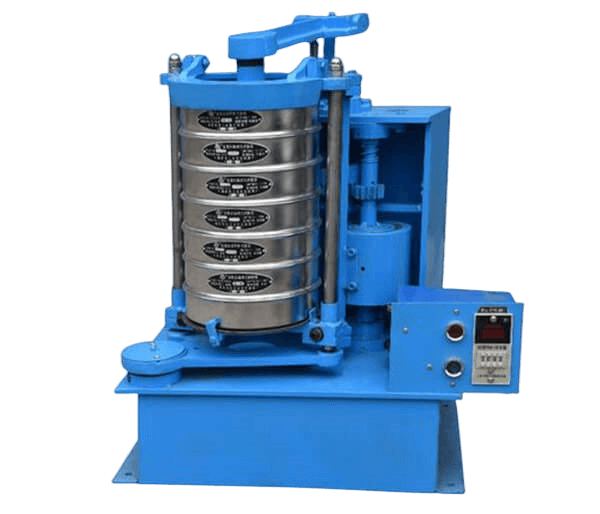

Diamond Powder Vibration Test SieveIt works with an vibration motor drive. This drive produces a 3D throwing motion that moves the material to be sieved equally over the whole sieving surface. Multi-layer standard lab analysis test sieve with timer is a new and precision equipment for continuously selecting / sifting / testing the diamond powder. It uses the new type vibrating motor as the source of vibration. |

|

|

Malvern

|